Exceptional printing services are crucial because they ensure the quality, professionalism and effectiveness of your printed materials.

Whether you are producing marketing brochures, banners, business cards, or any other printed media, high-quality printing can really affect how your brand is perceived.

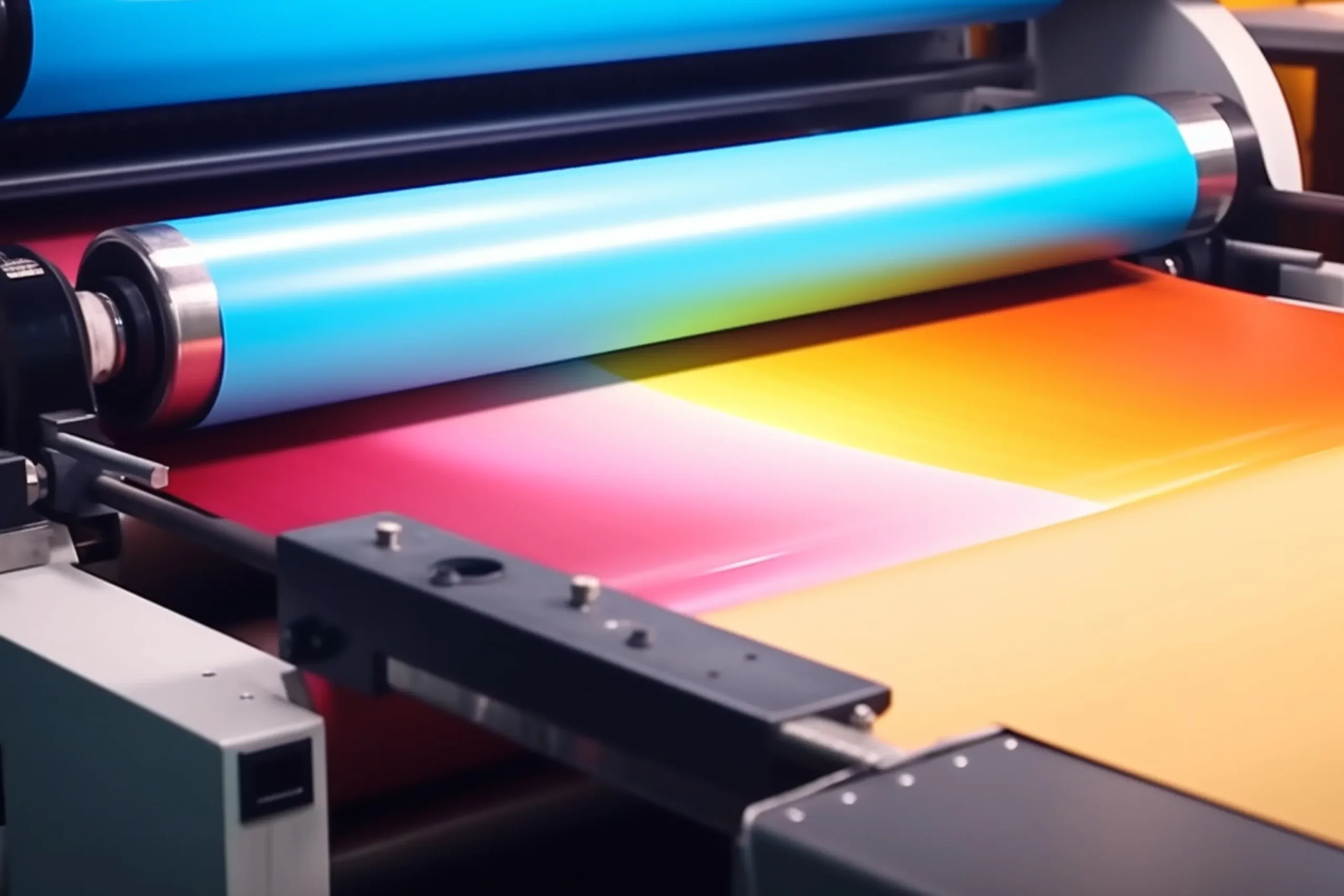

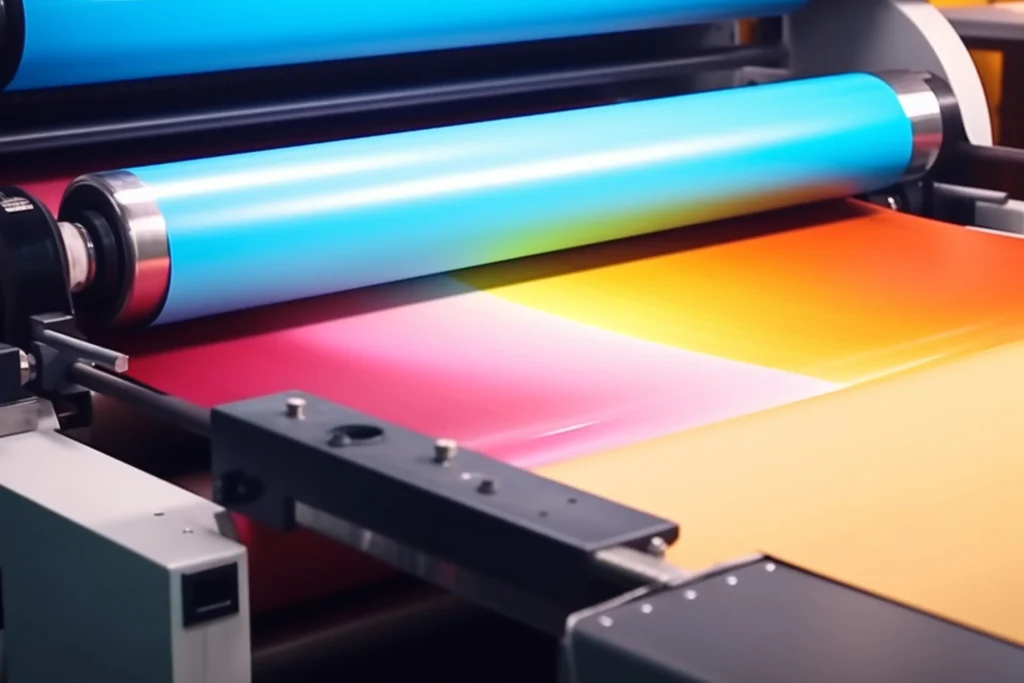

A major part of good services is the availability of full-color printing otherwise referred to as CMYK.

This method uses four main colors to come up with a wide range of vibrant and detailed images.

It could be for the glossy pages of a high-end magazine, eye-catching designs on brochures, or vivid reproductions of artwork, this method is integral in the production of rich and visually appealing prints. This article gives information regarding the intricacies of this technique by explaining the process involved and its different applications.

Overview of How It Works

Here are the different steps involved in the process:

Color Separation

To ensure that images are accurately produced with vibrant and precise colors, then color separation has to be conducted. During this stage, the original image is fragmented into four main colors – cyan, magenta, yellow, and black. Specialized software analyzes the image and creates a unique file for each of these colors. It then highlights different application points. These files are then used to create individual plates for every variation. This advanced separation of colors enables precise layering of inks during the procedure. This allows for the creation of a cohesive and high-quality image. Proper separation is crucial for achieving perfect color balance and maintaining the integrity of the initial design.

Plates Creation

As aforementioned, this is the next step that follows immediately after the separation is complete. The separated colors in the separation phase need their own plate. This process is done using a phytochemical or digital process where separated images are transferred onto the plates, which are usually made of metal. The plate for each color contains tiny etched patterns that correspond to the specific areas where that color ink is supposed to be applied. During the process, the plates are mounted onto the press, where they transfer ink onto the surface using rollers. The precision in plate creation makes sure that each color aligns perfectly with the others. This results in sharp, vibrant, and accurate reproductions.

Printing Process

The process then starts with the actual application of inks to the surface. At this stage, each of the color plates is loaded onto a press. As the press operates, it transfers ink from each plate onto the surface in a precise sequence. The ink is applied in tiny dots, which are perfectly positioned to blend. This helps create a good range of colors and shades. Each color is layered separately with careful registration to make sure that the colors align perfectly and produce a sharp and cohesive image. The surface, whether it is paper, cardstock, or another material moves through the press, receiving the ink as it goes.

Registration

This is the final but also important stage of the process because it helps ensure that the colors align perfectly to produce a sharp and accurate image. After each of the color plates has applied its respective ink to the surface, registration entails confirming the layers of ink are properly aligned. The alignment is done through careful calibration of the press with small adjustments made to ensure each color plate is correctly positioned relative to the others. This is an important part of the process to help prevent blurry or off-color prints.

Different Applications

In the marketing department, it is used for creating eye-catching brochures, flyers, and posters that effectively capture attention and communicate the needed message. In publishing, it enhances the visual appeal of magazines, books, and catalogs. Packaging and labeling also benefit from it because the colorful images and designs help to attract consumers and convey product information. In addition, the art world utilizes it to reproduce paintings and photographs.

Full-color printing stands as a cornerstone of modern printing, enabling the production of vibrant and quality images. The process encompasses different stages including color separation, plate creation, the actual printing, and registration. These are crucial phases to ensure perfect results. The versatility of this method allows it to be used in different areas such as packaging, marketing materials, art reproductions, and publications like magazines. To ensure the best possible results, be sure to get your prints done by a professional company. The reasoning behind this is that they will most likely have the needed tools and expertise to do an excellent job for you.